Home >Bearings >Rolling Mill Bearing >Tapered roller bearings >Four row tapered roller bearing(Inch size)

Contact Us

0086-411-66665948

0086-411-66665948 sales@dlrtr.com

sales@dlrtr.com joycewang323

joycewang323Products

Details

Tapered roller bearing features:

Tapered roller bearings have tapered inner and outer ring raceway, the tapered rollers installed between raceways. If we extend the cone surface, they will be eventually intersected at a point on the axis bearing.

Tapered roller bearings are mainly used to take mainly radial load from radial and axial joint load. The bearing axial load capacity is decided by the contact angle ’a’, the greater angle ‘a’, the greater the axial load capacity.

Tapered roller bearings are separable bearings with roller and the inner ring of the cage, constitute the inner components, can be installed with the outer ring separately.

The structure of tapered roller bearing

Double row tapered roller bearings:

350000 type: This type of bearings use a pair of raceway outer rings with and two inner rings, a spacer ring between the two inner rings. To change the thickness of the spacer ring, can adjust the bearing clearance. While takes the radial load, can also take two-way axial load.

370000 type: This type of bearings use a pair of raceway inner rings with and two outer rings, a spacer ring between the two outer rings. To change the thickness of the spacer ring, can adjust the bearing clearance. While takes the radial load, can also take two-way axial load.

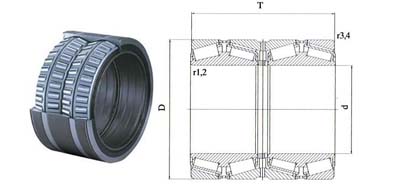

Four-row tapered roller bearings:

380 000 Type: this type of roller bearings use two double raceway inner rings, one double raceway outer ring and two single raceway inner rings。A double raceway outer ring and two single raceway outer rings, inner ring and outer rings—they all have spacer ring between them, which is used for adjusting clearance. This bearing can withstand higher radial loads and axial loads. However, it has low speed limits, mainly used for heavy machinery, such as rolling mill machines.

Tapered roller bearings, roll neck and bearing seat inner hole clearance fit

According to the working characteristics of hot rolling mill and cold rolling mill, the recommendations of bearing, roll neck and bearing seat inner hole clearance fit as following:

Bearing inner diameter and roll neck clearance fit: Recommend roller bearings inner diameter clearance fit uses on roller neck, which can meet the roller bearing inner ring creeps along the neck circumferentially, and also facilitates the installation and removal of rolls.

Bearing outer diameter and bearing seat inner hole clearance fit, it is related to the size of the bearing outer diameter, when the bearing outer diameter D <500mm, the tolerance of bearing seat inner hole size is recommended H7, when D> 500mm, the tolerance of bearing seat inner hole size is recommended G7.

Tapered Roller Bearing radial clearance choice:

As to the tapered roller bearings which carry the radial load (mainly) and axial joint load, the working conditions are extremely bad. In work, the actual clearance is related to carrying load, speed, lubrication, temperature rise, design structure and surface roughness etc. In the selection, it shall be based on the rolling mill situation analysis and determine the appropriate clearance of its value.

Dimensions (mm) |

|

|

Basic load rating (KN) |

|

Weight (kg) |

Number |

d |

D |

T |

|

|

|

|

|

|

|

Dynamic |

Staitc |

|

|

107.95 |

146.05 |

106.365 |

307 |

758 |

4.96 |

L521949D/L521910/521910D |

139.7 |

200.025 |

106.338 |

888 |

2020 |

15.9 |

48680D/48620D/48620D |

203.2 |

317.5 |

266.7 |

2100 |

5200 |

81 |

93800D/93125/93127D |

203.352 |

298.45 |

174.628 |

1470 |

2970 |

38 |

|

228.6 |

311.15 |

200.025 |

1630 |

4040 |

43.5 |

LM245149D/LM245110/LM245110D |

244.475 |

Previous :Thrust Full Tapered Roller Bearing

Next :Four Row Tapered Roller Bearing

Other Product+more